Radiant tubes for furnaces :

Heat-resistant Alloys

Material :

HI / JIS SCH18 / EN 1.4846 radiant tubes for furnaces are manufactured by centrifugal casting technique at LAWAI INDUSTRIAL CORPORATION in Taiwan.

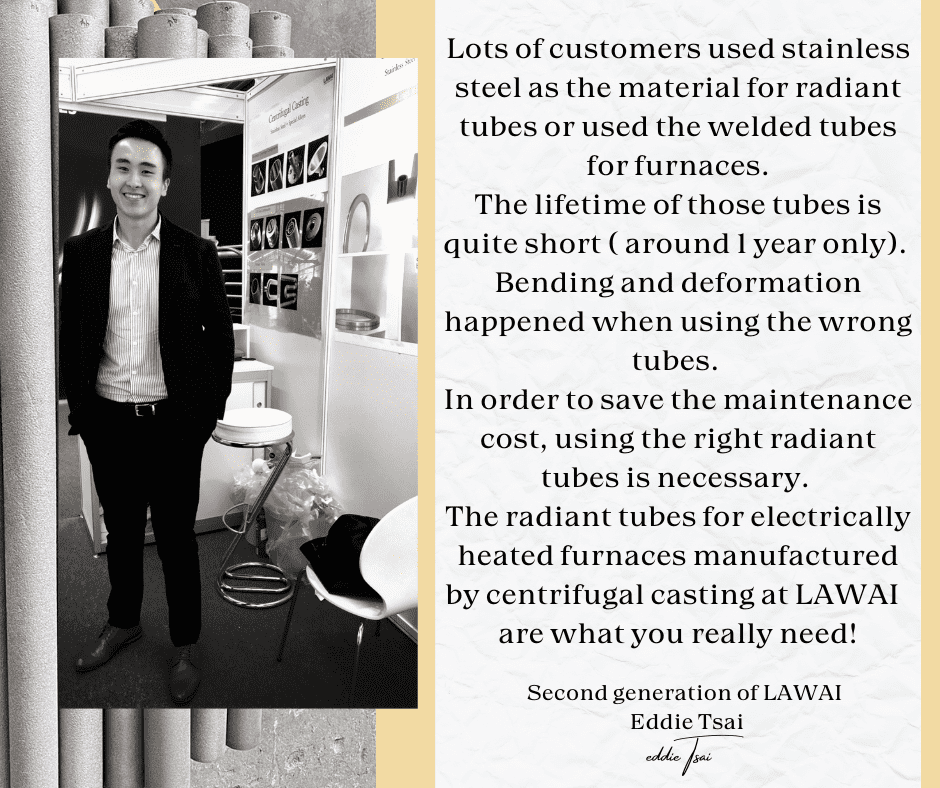

HI / JIS SCH18 / EN 1.4846 is the heat-resistant alloy suitable for using under high temperature environment. Centrifugal casting technique is the right manufacturing method to produce the radiant tubes for furnaces because the tubes are one-piece construction. Bending or deformation will not happen when using the HI / JIS SCH18 / EN 1.4846 radiant tubes produced at LAWAI in the high temperature condition for a long time (The lifetime of the radiant tubes could be longer than 5 years).

If you are looking for the HI / JIS SCH18 / EN 1.4846 radiant tubes for furnaces that are with long lifetime and long durability under high temperature, LAWAI’s custom radiant tubes will be the best choice!

If you have further questions, please contact us via the left form or email.

*Diameter > 50 mm

*Length 1000~3000 mm is what we do usually

*MOQ is based on the dimension

| Centrifugal Casting | Forging | Static Casting | |

|---|---|---|---|

| Provide Customized Alloy? | Yes, various materials can be cast. | No, there is the limitation of material selection. | No, there is the limitation of material selection. |

| Great quality? |

|

|

|

| Possible for small order quantity? Competitive price? |

Yes, small quantity would not change the price. | No, the cost of mold is high and the price would be competitive only when ordering several ton order weights. | No, it is not suitable for small quantity production. |

| Cost advantage? | Yes, it's more cost-effective. | No. | It's cost-effective for "large" order quantity. |

LAWAI - Centrifugal Casting

LAWAI is the family-run centrifugal casting manufacturer in Taiwan.

We've produced symmetric components since 1989.

Pioneer of centrifugal casting in Taiwan

LAWAI uses the recycled stainless steel scrap to manufacture centrifugal castings.

- The quality of centrifugal castings is the same as those made of raw materials

- Turning the scrap (some people regard it as trash) into the stainless steel ingots

- Minimizing the carbon footprints, making our world sustainable

- Practicing circular economy thoroughly

Manufacturing your products in the way that is best for you

LAWAI manufactures the custom products by centrifugal casting that are superior and functional.

- Flexible order quantity to meet your small projects

- Standard grade to high grade specially steel to meet your applications

- Rough to finish machining to meet your special needs

- Safe packing method to protect customers’ rights

LAWAI is the No. 1 AISI Radiant tubes for furnaces manufacturer in Taiwan. We provide customized AISI Radiant tubes for furnaces for our clients all over the world. The AISI Radiant tubes for furnaces in LAWAI – reliable and beyond your expectation!