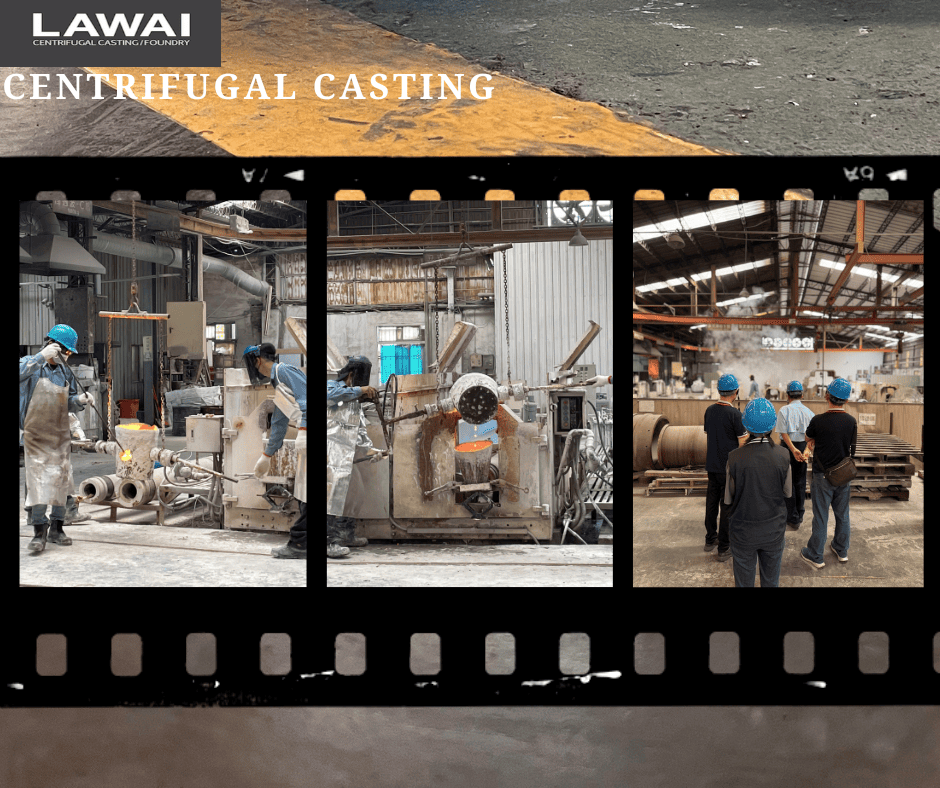

What is the best technique to produce ASTM A297 HH Type 2 / JIS SCH13 / EN 1.4837 heat-resistant conveyor rollers?

Centrifugal casting is one of the good choices!

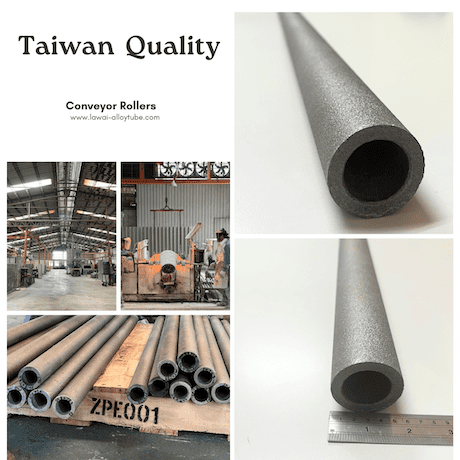

In order to fit in different temperature environment, heat-resistant conveyor rollers should be customized. Stainless steel and heat-resistant steel are the materials for heat-resistant conveyor rollers. Heat-resistant alloys such as ASTM A297 HH Type 2 / JIS SCH13 / EN 1.4837 were formulated for casting. It is quite difficult to be produced by forging. If customer need the conveyor rollers applied in high temperature environment, ASTM A297 HH Type 2 / JIS SCH13 / EN 1.4837 centrifugally cast conveyor rollers will be the priority undoubtedly.

The dimensions we produce for ASTM A297 HH Type 2 / JIS SCH13 / EN 1.4837 heat-resistant conveyor rollers:

The outer diameter is over 50 mm

If you need the heat-resistant conveyor rollers that could resist oxidation & avoid bending under high temperature and bear the heavy load, ASTM A297 HH Type 2 / JIS SCH 13 / EN 1.4837 centrifugally cast conveyor rollers made at LAWAI will be satisfying!

Please contact us via the left form or email.

email: [email protected]

Follow LAWAI on FACEBOOK & INSTAGRAM

| Centrifugal Casting | Forging | Static Casting | |

|---|---|---|---|

| Provide Customized Alloy? | Yes, various materials can be cast. | No, there is the limitation of material selection. | No, there is the limitation of material selection. |

| Great quality? |

|

|

|

| Possible for small order quantity? Competitive price? |

Yes, small quantity would not change the price. | No, the cost of mold is high and the price would be competitive only when ordering several ton order weights. | No, it is not suitable for small quantity production. |

| Cost advantage? | Yes, it's more cost-effective. | No. | It's cost-effective for "large" order quantity. |

LAWAI is the family-run centrifugal casting manufacturer in Taiwan.

We've produced symmetric components since 1989.

Pioneer of centrifugal casting in Taiwan

LAWAI uses the recycled stainless steel scrap to manufacture centrifugal castings.

- The quality of centrifugal castings is the same as those made of raw materials

- Turning the scrap (some people regard it as trash) into the stainless steel ingots

- Minimizing the carbon footprints, making our world sustainable

- Practicing circular economy thoroughly

Manufacturing your products in the way that is best for you

LAWAI manufactures the custom products by centrifugal casting that are superior and functional.

- Flexible order quantity to meet your small projects

- Standard grade to high grade specially steel to meet your applications

- Rough to finish machining to meet your special needs

- Safe packing method to protect customers’ rights

Roller

%20produced%20by%20centrifugal%20casting%20in%20Asia-LAWAI%20INDUSTRIAL%20CORPORATION.png)