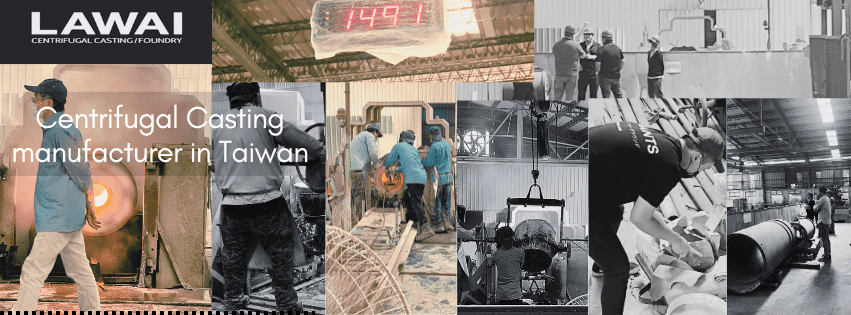

LAWAI INDUSTRIAL CORPORATION is the centrifugal casting sleeve manufacturer in Taiwan.

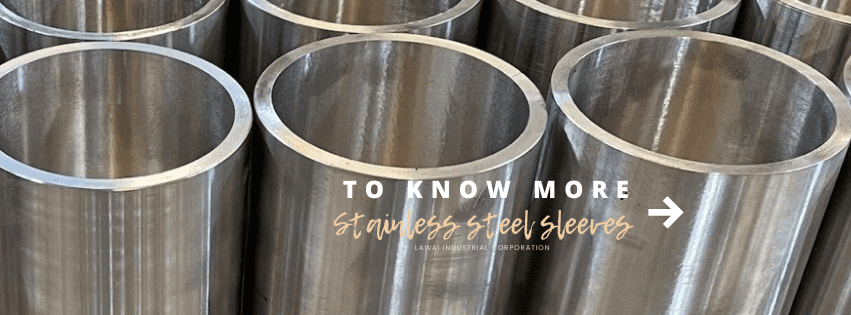

Centrifugal casting technique is the very cost-effective method to produce symmetrical and cylindrical products. Stainless steel CA15 / 410 centrifugal casting sleeves are the popular centrifugal casting materials of the key components applied in several industries including pump, marine, chemical, food, oil & gas industries …etc.

Why choosing CA15 / 410 centrifugal casting sleeves produced at LAWAI ?

- None-pores and easy to be machined

- Customization to meet exact dimensions customer require

- Lower quantity is able to be produced

- The mechanical properties are almost equal to forging

- Taiwan quality is irreplaceable

Over 30 years’ experience in centrifugal casting in Taiwan, the fruitful experience and mature technique make each LAWAI’s CA15 / 410 centrifugal casting sleeve used well in different industries.

If you have the demands of stainless steel CA15 / 410 sleeves produced by

| Centrifugal Casting | Forging | Static Casting | |

|---|---|---|---|

| Provide Customized Alloy? | Yes, various materials can be cast. | No, there is the limitation of material selection. | No, there is the limitation of material selection. |

| Great quality? |

|

|

|

| Possible for small order quantity? Competitive price? |

Yes, small quantity would not change the price. | No, the cost of mold is high and the price would be competitive only when ordering several ton order weights. | No, it is not suitable for small quantity production. |

| Cost advantage? | Yes, it's more cost-effective. | No. | It's cost-effective for "large" order quantity. |

LAWAI is the family-run centrifugal casting manufacturer in Taiwan.

We've produced symmetric components since 1989.

Pioneer of centrifugal casting in Taiwan

LAWAI uses the recycled stainless steel scrap to manufacture centrifugal castings.

- The quality of centrifugal castings is the same as those made of raw materials

- Turning the scrap (some people regard it as trash) into the stainless steel ingots

- Minimizing the carbon footprints, making our world sustainable

- Practicing circular economy thoroughly

Manufacturing your products in the way that is best for you

LAWAI manufactures the custom products by centrifugal casting that are superior and functional.

- Flexible order quantity to meet your small projects

- Standard grade to high grade specially steel to meet your applications

- Rough to finish machining to meet your special needs

- Safe packing method to protect customers’ rights